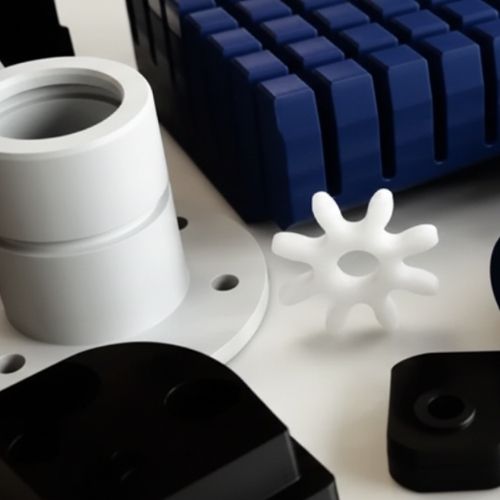

We don’t just supply high-quality semi-finished plastics; we engineer solutions. As a leading UK plastic stockist and supplier, we offer engineering and semi-finished plastics, expertly machined and delivered to businesses across the country.

As a leading UK plastics machinist, we know that precision and quality count in modern engineering. Whether it’s a high-wear guide rail for a conveyor system or a complex manifold for a chemical processing plant, the transition from stock to precision requires a deep understanding of our materials and cutting-edge technology.

The art of CNC machining

Precision CNC plastics machining is vital when producing high-quality, engineered parts. Unlike metal machining, where heat dissipation is managed through mass and coolant, plastics require a more refined approach. Our engineering plastics have higher thermal expansion rates and lower melting points than their metal counterparts, so if handled and machined in the same manner as metal, there is a risk of deformation, internal stress, and poor surface finishes.

Our approach combines decades of technical expertise with the latest in 5-axis and 3-axis CNC technology. This allows us to achieve the tightest tolerances, ensuring that every component we produce meets the exact specifications of industrial projects.