Recreating Complex Components with Confidence

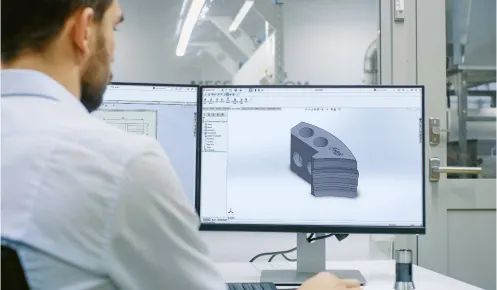

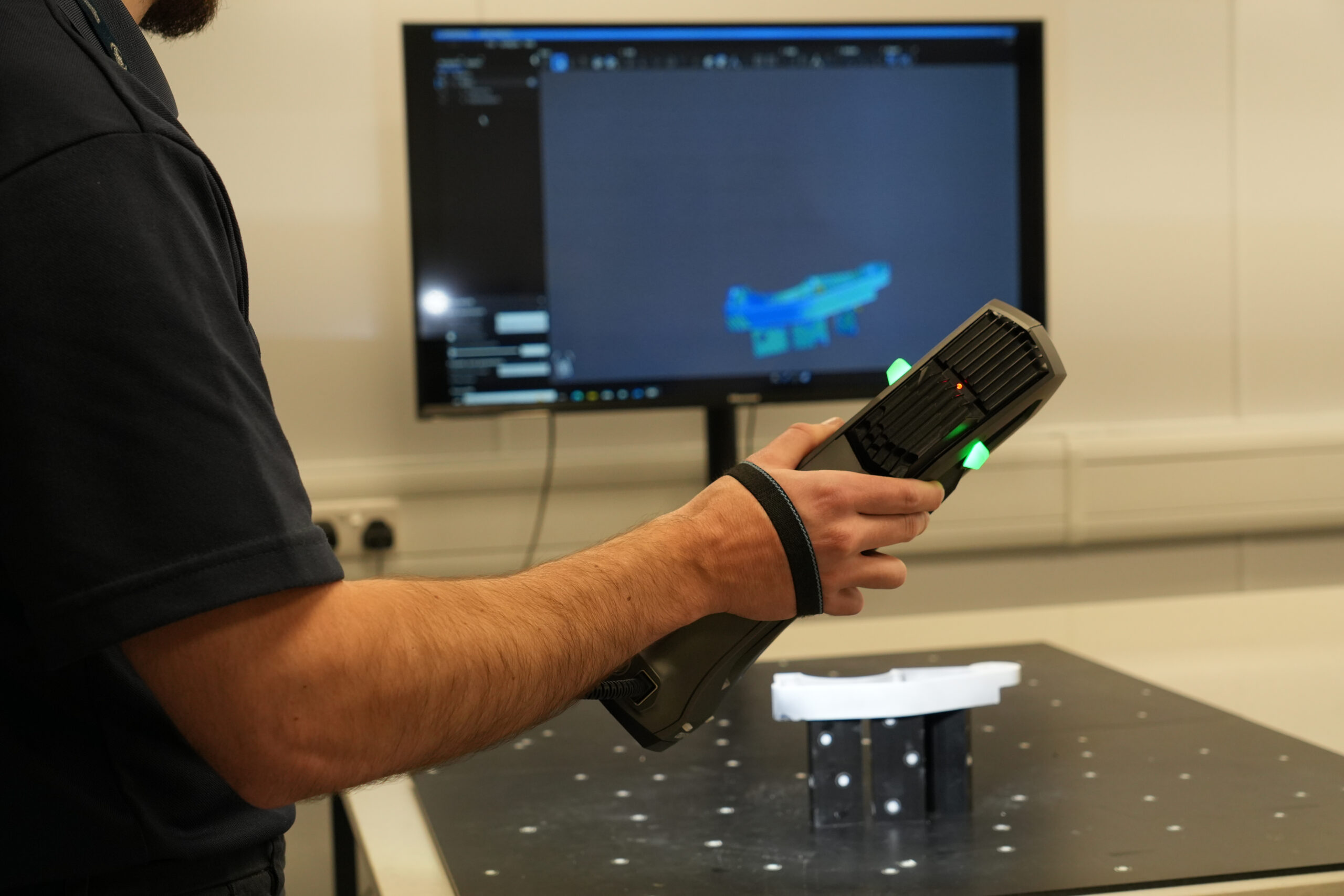

Using advanced 3D scanning and digital measurement technology, our technical team can capture even the most intricate geometries. Whether you’re replacing a worn component, improving an existing design, or adapting a part for a new application, we can accurately reproduce it using the latest software and machinery.

Our in-house capabilities include Mitutoyo measurement equipment, Creaform 3D scanning, and SolidWorks CAD modelling, allowing us to create reliable digital replicas ready for precision machining. This process ensures that every replacement or modified component meets tight tolerances and performs seamlessly within its operating environment.

Technical Insight That Adds Real Value

Reverse engineering is just one part of the wider support we offer. Oadby’s Technical Team works with customers from early-stage concept and estimating through to production, offering guidance on materials, tolerances, and machining strategies.

This input often leads to:

- Reduced lead times through accurate upfront planning

- Improved component life by refining design or material selection

- Less waste through optimised cutting and machining techniques

By aligning our expertise with each customer’s performance goals, we help ensure every part is both cost-effective and built to last.

Quality Assurance at Every Stage

Every component we produce undergoes inspection under our ISO 9001-accredited quality management system. This ensures consistent accuracy, whether for one-off replacements or high-volume production runs. Our quality assurance processes are integrated throughout machining and inspection, so customers can rely on every part meeting specification before it leaves our facility.

Partnership Built on Precision

For many of our customers, the greatest value lies in the combination of technical skill and open collaboration. We don’t just recreate parts; we help improve them, using our knowledge of plastics behaviour, machining tolerances, and real-world application demands to enhance performance.

Whether you’re facing an urgent breakdown or developing a new component from scratch, Oadby Plastics has the technology, experience, and expertise to deliver results with accuracy and reliability.

Speak to our Technical Team to discuss your next project or learn how our reverse engineering capabilities can help you maintain precision and performance across your operations.