Why Manufacturers Are Turning to Plastics

Modern engineering plastics such as nylon (PA6), acetal (POM-C), polyethylene (PE), and polycarbonate (PC) are designed to meet demanding operating conditions. These materials perform exceptionally well in moving parts, fluid systems, and load-bearing applications where reliability is critical.

By choosing the right material for each component, manufacturers can achieve smoother operation, longer service life, and improved energy efficiency. Plastic components can also help to reduce noise and vibration, protecting machinery and improving the working environment.

Where Engineering Plastics Deliver Results

Engineering plastics are now a mainstay in industries where precision, safety, and cleanliness are non-negotiable. In food and beverage processing, for example, plastics like PE and acetal are ideal for wear strips, star wheels, and conveyor components thanks to their low friction and easy-clean surfaces.

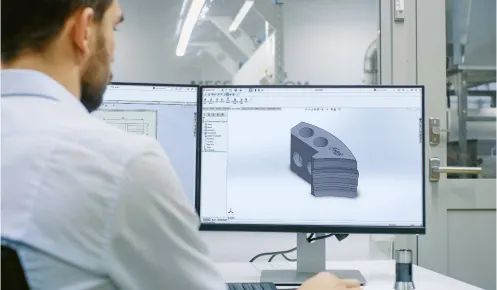

In packaging and automation, lightweight machined plastics reduce the strain on moving parts and extend equipment life. Meanwhile, engineering and manufacturing sectors benefit from the excellent dimensional stability and machinability of technical plastics, which allow complex, high-tolerance parts to be produced quickly and consistently.

Oadby Plastics: Supporting Smarter Manufacturing

At Oadby Plastics, we supply one of the UK’s widest ranges of engineering plastics, alongside precision CNC machining and expert technical advice. Our team works closely with customers to recommend the right material for each application — whether it’s a one-off prototype or a large-scale production run.

With 250,000 sq. ft of stockholding and a 50,000 sq. ft machining facility, we ensure every order is delivered with the precision and reliability that modern manufacturing demands.

If you’re exploring how engineering plastics could improve your manufacturing performance, speak to our technical sales team for expert guidance.