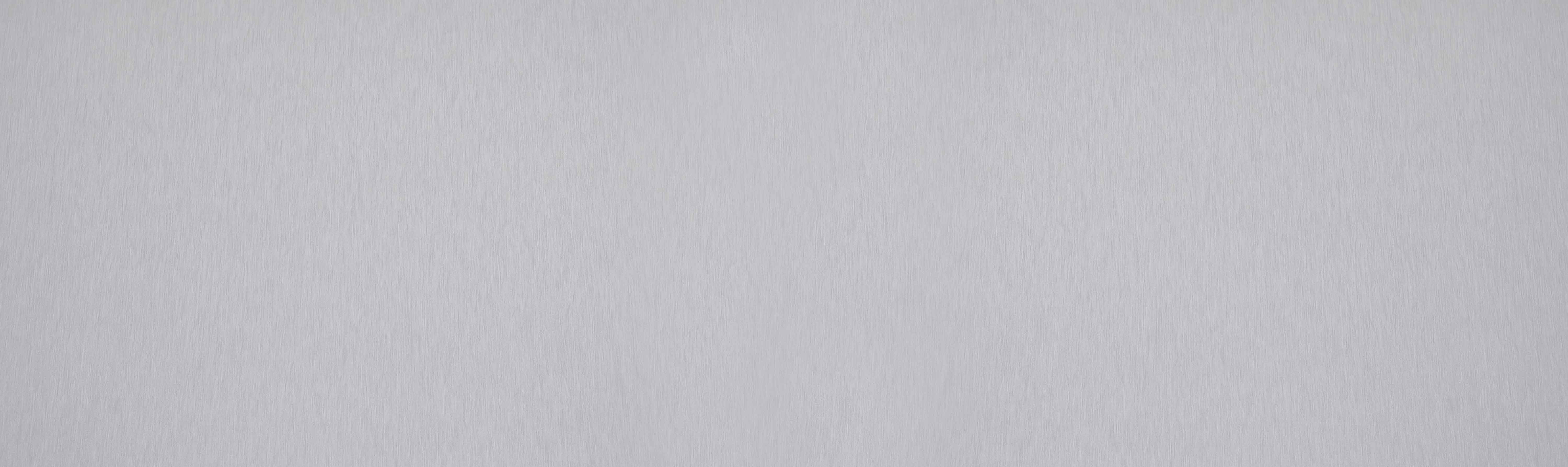

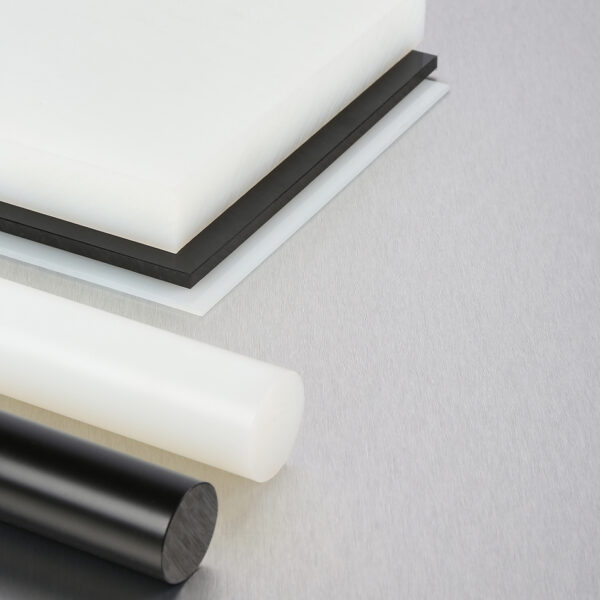

How does Nylon 6 Cast compare to Nylon 6 Extruded?

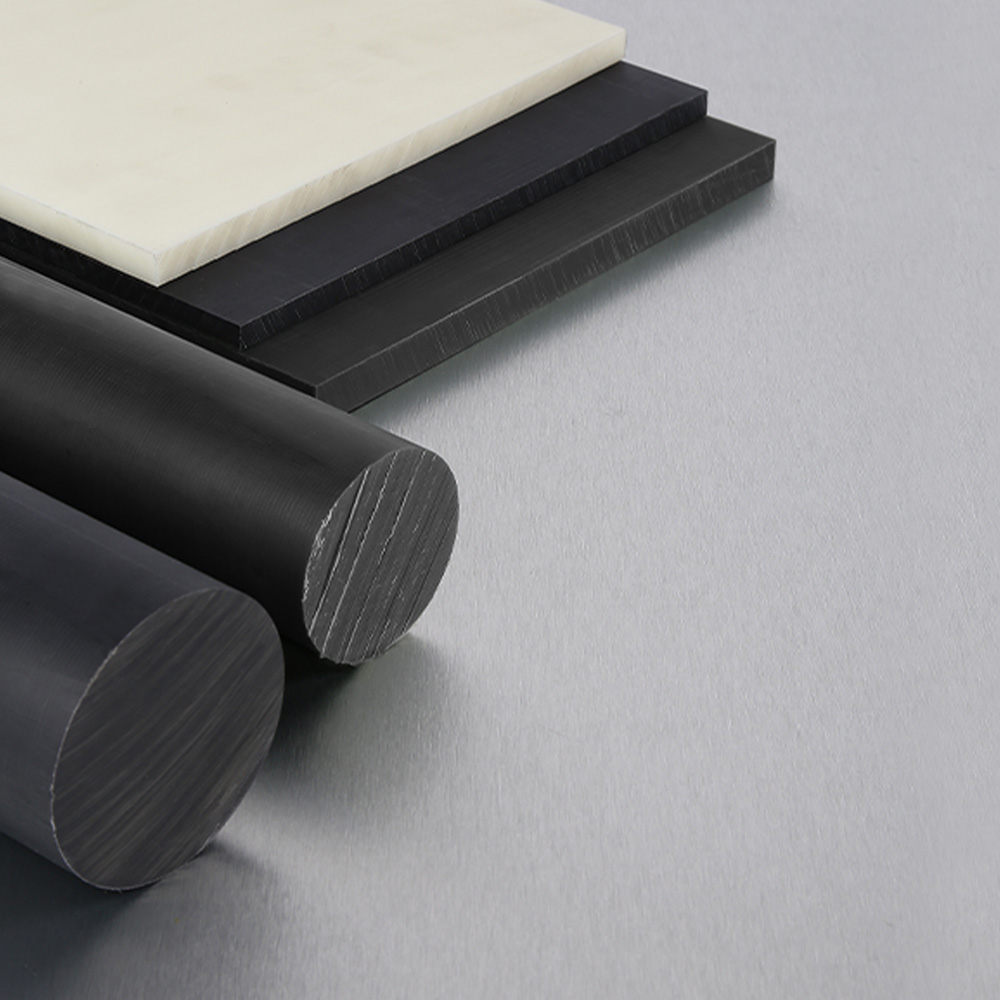

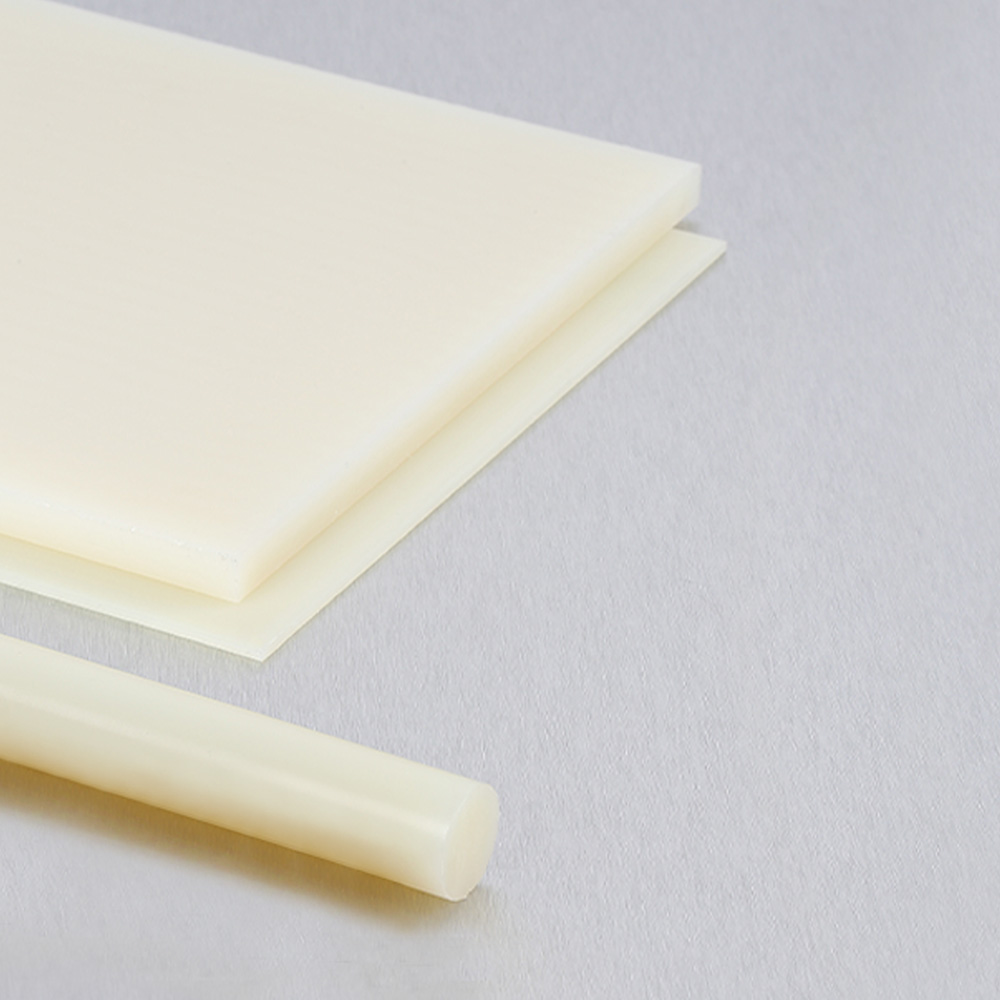

Nylon 6 Cast offers improved mechanical properties, including higher strength and stiffness, better wear resistance, and enhanced machinability compared to Nylon 6 Extruded, making it more suitable for demanding applications.