Material guide by application, with ready-to-stock options

High-precision machined parts, gears, and manifolds:

Acetal (POM-C copolymer and POM-H homopolymer) for excellent machinability, low friction, and stability. For contamination control in food lines, specify metal-detectable Acetal (POM-MD).

Load-bearing parts that must hold tight tolerances:

PET and PET ZX. Standard PET offers dimensional stability and low moisture absorption, making it ideal for pulleys and wear pads. PET ZX adds a lubricant or PTFE-based filler for reduced friction where lubrication is limited.

Wear strips, chain guides, impact plates:

PE 1000 (UHMW-PE) for superb abrasion resistance and impact strength. Where you need even lower friction and longer life, choose UHMW with dry lubricant enhancements.

Bushes, rollers, and robust mechanical parts:

Nylon 6 or 66 variants, with options for filled and self-lubricating grades. Choose stabilised or food-contact grades where required. Note that Nylon absorbs moisture, so account for dimensional changes in tight-tolerance builds.

Building services and utilities:

uPVC sheet and foams for cladding, partitions, signage, and hygienic walling. Use CPVC where hot water or higher service temperatures are present, up to around 95°C. Match grades to indoor or outdoor exposure as required.

Chemical tanks, ducting, and process plant:

PP homopolymer (PPH) for higher stiffness and chemical resistance than PPC, with continuous service typically up to 100°C. Use extruded PPH for general fabrications. Choose pressed & planed PPH where you need flatness, thickness accuracy, and a stress-relieved plate for tight-tolerance machining of panels and flanges.

PP copolymer (PPC) for improved toughness at lower temperatures and good weldability in cladding and fabrications.

When to specify FR grades:

Use PPH-FR or PPC-FR where panels or enclosures require enhanced fire performance, for example, HVAC housings, lab furniture panels, or covers in controlled environments. Confirm the required test method and classification before ordering.

Aggressive chemistry or elevated temperature:

PVDF for outstanding chemical resistance, low permeability, and FDA-compliant grades. PEEK for high temperature, strength, and chemical resistance in demanding environments, and where metal replacement is being evaluated.

Clear, display, and guarding needs:

Acrylic (cast or extruded) for optical clarity and UV resistance. Cast acrylic is preferred outdoors. Polycarbonate is an option when higher impact resistance is critical, subject to chemical environment.

When to use pressed & planed PPH

Select pressed & planed PPH when your application demands:

- Flat, stress-relieved plate that stays stable after machining.

- Tight thickness tolerance across large panels.

- Chemical resistance and stiffness for flanges, baffles, and tank plates that must bolt up and seal correctly.

Use extruded PPH for general fabrications and welded assemblies where post-machining flatness is less critical.

When to specify flame-retardant grades

If your risk assessment or specification requires improved fire resistance, consider upgrading to PPH-FR or PPC-FR. These grades are suited to ducts, cabinets, lab and HVAC panels, and equipment covers in sensitive areas. Confirm the standard and rating required for your site or sector before making a selection, and request supporting documentation during your enquiry.

When to consider lubricant or PTFE-filled materials

Use PET ZX, UHMW with dry lubricant, or PTFE-filled grades where:

- You cannot rely on external lubrication.

- You need lower starting friction and reduced stick-slip.

- You want longer wear life on conveyors, cams, or sliders.

Note that PTFE or lubricant-filled grades can be harder to bond. Mechanical fastening or specialist adhesives and trials are recommended.

Which plastics handle high wear, chemicals, or food contact?

- High wear: UHMW-PE (PE 1000) for abrasion and impact; PET ZX and self-lubricating Nylon for sliding parts; Acetal for balanced wear with tight tolerances.

- Chemical resistance: PPH and PPC for many acids and alkalis, PVDF for aggressive media, CPVC for hot water and many chemicals.

- Food contact: Selected grades of Acetal, PET, PVDF, and Nylon. For contamination control, specify metal-detectable Acetal. Always confirm grade-specific approvals and request certificates.

How UK manufacturers source semi-finished plastics reliably

- Prioritise stockholding: choose a partner with large on-hand inventories and a broad range of engineering plastics ready to cut. Oadby Plastics holds over 3,000 tonnes of stock across our extensive UK warehousing.

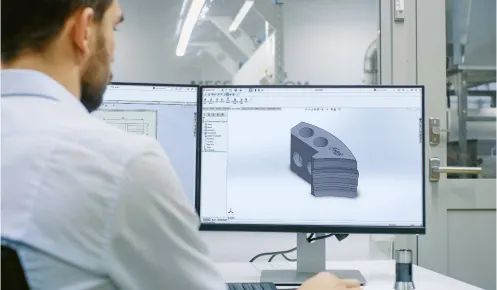

- Keep supply and machining under one roof: cut-to-size, routing, milling, and turning in-house reduce handling time and risk. If you need components as well as material, our facility supports prototype to volume with full QA.

- Utilise dependable logistics: our own nationwide fleet ensures scheduled, on-time delivery with clear communication and regular order updates.

- Request technical support and QA: engage early for material selection, drawing review, compliance guidance, and documentation packages.

If you need an experienced engineering plastics supplier for fast and dependable delivery, explore our range of engineering plastics and enquire about our tailored advice, samples, and certification.

Useful next steps

- Review polyethylene plastic options for wear applications and conveyor systems.

- If you need parts as well as material, our cnc plastic machining service can programme, machine, inspect, and deliver to drawing with full traceability.

- Planning a broader material supply programme, framework agreement, or VMI, talk to our team to align stockholding and delivery schedules to your site needs.

Summary

Engineering plastics give you strength, stability, wear life, and compliance that commodity materials cannot deliver in production environments. Start with the five-point selection framework, then choose from proven stock grades, from Acetal and Nylon to PET, UHMW-PE, PP, PVDF, PEEK, acrylic, uPVC, and CPVC. When you need flat, stress-relieved plate for precision panels, pick pressed & planed PPH. Where fire performance matters, specify FR grades. For dry-running applications, consider lubricant or PTFE-filled options.

Oadby Plastics combines extensive stockholding, cut-to-size and machining capability, technical guidance, and a nationwide transport fleet so you get the right material, on time, with the documentation you need.

Enquire today to secure reliable supply for your next project.