1. Define Your Environment and Application

Every project operates in unique conditions. The temperature, load, moisture, and even cleaning process your part or component is exposed to will determine which material performs best.

For example:

✔️ Food and beverage production often requires hygienic, easy-to-clean plastics like HDPE or Acetal, offering excellent moisture and bacteria resistance.

✔️ Engineering and mechanical systems benefit from materials like Nylon or POM-C, known for strength, stability, and wear resistance.

✔️ Chemical or water treatment systems demand durable options such as PVC or Polypropylene for superior chemical resistance and machinability.

If you’re still unsure, our technical sales teams work closely with customers to understand their applications, ensuring every recommendation aligns with the real-world demands of the environment. They’d be happy to help discuss your requirements, too.

2. Balance Performance, Longevity and Cost

It’s tempting to select a familiar or low-cost material, but small differences in specification can have a major impact on the outcome. The right plastic can reduce downtime, extend part life, and even enhance safety.

At Oadby Plastics, we help customers weigh up key factors such as:

- Load-bearing strength and mechanical stress

- Friction, wear, and surface finish

- Exposure to UV, heat, or chemicals

- Machinability and ease of fabrication

By analysing these performance indicators, our experts help you achieve the best balance of cost, reliability, and efficiency, ensuring your investment works harder for your business.

3. Choose a Partner That Delivers More Than Material

The best results come from combining quality materials with precision manufacturing.

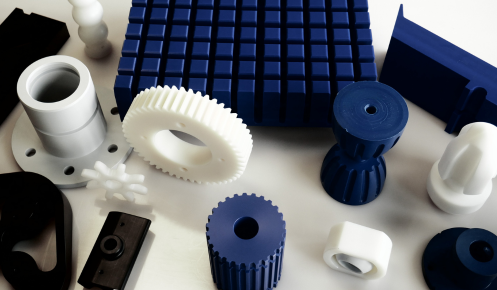

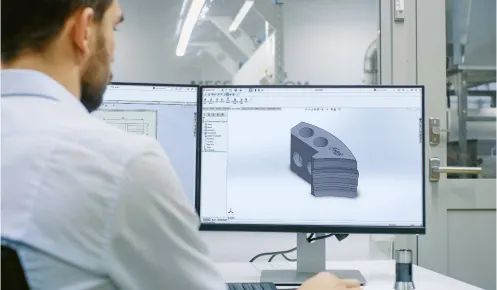

With over 3,000 tonnes of stock and a 50,000 sq. ft CNC machining facility, Oadby Plastics provides a complete, end-to-end service; from semi-finished sheets and rods to bespoke, precision-milled components.

Our advanced machining capabilities include 5-axis CNC technology, ensuring every component meets exact specifications, tolerances, and surface finishes. Whether you need a prototype or a high-volume production run, our team guarantees accuracy, repeatability, and fast turnaround across every order.

Confidence in Every Choice

Choosing the right plastic doesn’t need to be complicated. With half a century of expertise, national stockholding, and in-house machining, Oadby Plastics makes it easier to get the right solution the first time.

Ready to find the right material? Our experts can help you navigate the full material range, or you can use our Product Finder tool to identify the most suitable options for your project.